There are several ways you get to know when there’s something wrong with any vehicle whether a car or a truck. Cranking sounds from the engine, vibration or jerkiness, hard starts, poor fuel economy, or overheating.

But in most cases, before these symptoms become obvious, the vehicle’s computer would have informed the driver either by flashing an indicator light or displaying a code (that corresponds to the problem being detected) on the dashboard. These codes are known as trouble codes or fault codes and the ECU 128 code is one of them.

- What does the ECU 128 code indicate on your Freightliner?

- What are the common causes of the ECU 128 code in Freightliner trucks?

- Diagnosing and troubleshooting the ECU 128 code

- Can the ECU 128 code affect the overall performance of my Freightliner?

- Can the ECU 128 code be cleared once the issue is resolved, and how is this done?

- Are there any known recalls or service bulletins related to the ECU 128 code in Freightliner trucks?

- Are there any specific preventative maintenance steps I can take to avoid the ECU 128 code?

- What is the estimated cost and time required for repairing issues related to the ECU 128 code?

- Closing thoughts

What does the ECU 128 code indicate on your Freightliner?

The ECU 128 code in Freightliners is similar to the check engine light. It is not a fault code on its own, however, it indicates that there is a problem with the engine which can easily be diagnosed with a scanner.

To understand what the ECU 128 code means, it is important to know what it is the ECU does. Known as the engine computer or brain box, the ECU plays a central role in monitoring the performance of various components of the engine and ensuring they are working properly.

Modern engines are very sensitive and slight changes in operating conditions like temperature, fuel-air intake, oxygen level, oil level, emission level, and even the transmission system can have a negative impact on its performance.

To avoid this, the ECU constantly monitors the different engine components with the help of sensors and if any one of these components has failed or isn’t working properly, the ECU will immediately alert the driver either with warning lights or error codes.

Most cars will either display the error code on the dashboard with a warning message or just turn on the check engine light. The check engine light doesn’t specifically define the problem as clearly as an error message would. So whenever you see the check engine light, it means there could be any number of faults under the hood and you’ll need to run a diagnostic check to know exactly what triggered the check engine light.

What are the common causes of the ECU 128 code in Freightliner trucks?

Just like the check engine light, there are many possible causes of the ECU 128 code. Here are six common causes of the ECU 128 code on a Freightliner.

Faulty pressure sensor – oil pressure sensor monitors the oil pressure within the engine. Oil acts as a lubricant in the engine and without it, many things could go wrong. Without the oil pressure sensor, it is impossible for the ECU to know if the oil pressure is at the standard level, and if the sensor isn’t sending any signal to the ECU, it immediately triggers the ECU 128 code.

Faulty engine temperature sensor – Another component that could trigger the ECU 128 code is a faulty engine temperature sensor. This sensor measures the engine temperature to make sure it is well within the allowable operating temperature.

Faulty battery – The battery helps to power the electrical components in the Freightliner. The ECU 128 code will be triggered if the battery shows any signs of damage like not holding enough charge or if it has been completely discharged and is incapable of charging.

Vehicle speed sensor – This sensor measures the rotational speed of the wheel. It provides information that the ECU uses to determine when to turn on the traction control system and many other important functions.

Crankshaft position sensor – this sensor monitors the position and rotational speed of the crankshaft. The ECU uses the information from this sensor to control fuel injection as well as ignition system timing.

Fuel injector sensor and Mass Air Flow Sensor – The fuel injector or fuel rail pressure sensor monitors the pressure of fuel in the injectors. While the Mass airflow sensor monitors the flow rate of air entering the injector. Both sensors help the ECU determine the fuel-air mixture and to ensure the right amount is fed into the engine.

It is possible that a dirty MAF sensor can be the culprit. Giving it a good clean might resolve the issue, but is not guaranteed.

Faulty Throttle position sensor – This is another sensor that monitors the air intake of the engine as well as the throttle position.

A problem with the ECU – The ECU received feedback from several sensors to fine-tune the engine’s performance. And just like the various components it monitors, the ECU can also become faulty and this will cause the ECU 128 code to show up on the Freightliner.

Diagnosing and troubleshooting the ECU 128 code

The ECU 128 code on its own isn’t a fault code but more of a warning sign that there is a problem with the engine. Therefore to know what triggered the code, you’ll have to troubleshoot the ECU and get the error code behind it. Each error code corresponds to a specific component or system within the engine.

Here is what you need to do:

Step 1: Get the right tools

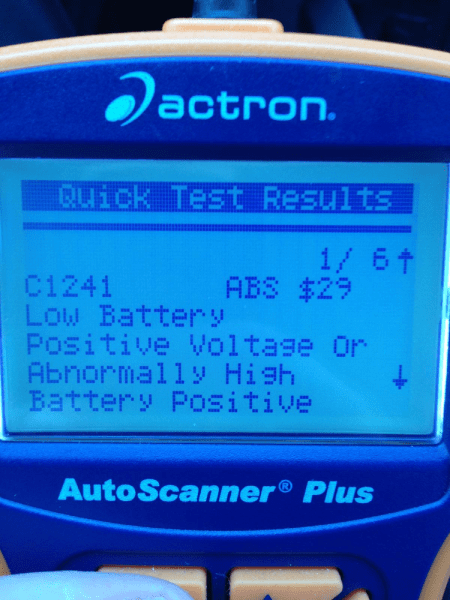

To start diagnosing the ECU 128 code, you’ll need an OBD-II scanner and diagnostic manual for your specific Freightliner model. This will help you identify what the fault code means and which component or system it relates to.

Step 2: Connect to the OBD-II port

Locate your vehicle’s OBD-II port (usually under the dashboard) and connect your scanner to it. Turn on your scanner and let it power up.

Step 3: Read fault codes

Follow the instruction on your scanner manual to read any available fault codes from the ECU. The error code will be displayed alongside some explanation of what it signifies.

Step 4: Identify other symptoms

Note down any additional symptoms that may have occurred with this fault – such as warning lights, engine misfires, unusual noise or reduced performance.

Step 5: Check wiring and connectors

Check all wires, fuses, relays, connectors thoroughly within that area of malfunctioning according to its corresponding error code in relation with ecu-128.

Step 6: Inspect components

If there are no problems found with wiring or connections

, you will need to inspect the relevant components according to the error code. For example, if the error code indicates a problem with the fuel system, you may need to check the fuel injectors or fuel pump.

Step 7: Follow repair procedures

Once you have identified which component causing an issue and it needs repairs, follow the repair procedure as described in your diagnostic manual. This may involve replacing parts or repairing broken wiring. Make sure that all work is done carefully and safely.

Step 8: Clear fault codes and test drive

After any necessary repairs have been made, clear all fault codes from your scanner using its “clear” function. Then take your vehicle for a test drive. Monitor for any warning lights or unusual symptoms once again if they reoccur with another fault code then consult a professional mechanic for further assistance.

Can the ECU 128 code affect the overall performance of my Freightliner?

Yes. The ECU 128 code is directly related to the engine. What this means is that the code only shows up whenever there is a problem within the engine. Since the ECU receives input from different sensors and uses this to fine-tune the engine’s performance, it, therefore, means that a faulty sensor sending incorrect signals to the ECU will have a direct impact on the performance of the engine.

Take for instance the mass air flow sensor. If the sensor is sending in the wrong measure of air entering the injector, then the ECU will calculate the wrong fuel-air mixture and this will either result in a lean or rich mix. A lean mix means more air than fuel and a rich mix means more fuel than air. Either one of these incorrect mix ratios will cause the engine to underperform.

Can the ECU 128 code be cleared once the issue is resolved, and how is this done?

The ECU 128 code should be cleared once the problem that triggered the code is resolved. But in some cases, the code could persist even after the cause has been resolved. In that case, the only thing left to do is hard resetting the ECU. Luckily this isn’t as difficult as it sounds. All you need to do is unplug the battery terminals for 30 minutes before reconnecting them. This allows all electrical power in the engine to be completely drained out. The ECU 128 should be cleared out by the time the battery terminals are reconnected.

Are there any known recalls or service bulletins related to the ECU 128 code in Freightliner trucks?

Yes. Freightliner trucks have had their fair share of service recalls. In 2022, more than 1000 Freightliner trucks were recalled due to an issue related to the ECU. The affected Freightliner trucks included the FREIGHTLINER/108SD/2023, FREIGHTLINER/114SD/2023, FREIGHTLINER/BUSINESS CLASS M2/2023, and the FREIGHTLINER/CASCADIA/2023

It was determined that the ECU on the affected trucks may experience an internal short circuit that will cause the engine to fail.

Worth mentioning is the Takata Airbag Inflator recall in 2021 where some freightliner sprinter vans fitted with the Takata airbags had to be recalled due to the safety concerns raised by the National Highway Traffic Safety Administration (NHTSA). According to the NHTSA, the Takata airbags and inflators were defective and could explode causing injury or death.

There was another recall in 2023 related to an issue with the windshield wiper where it was determined that the wiper linkages could break and cause the wiper to fail. This led to about 54,000 Freightliner trucks being recalled.

Are there any specific preventative maintenance steps I can take to avoid the ECU 128 code?

Preventing the ECU 128 code is impossible because regardless of how well you maintain the truck, some components eventually fail and must be replaced. In light of this, the best cause of action is to watch out for any sign of a failed component and immediately fix it to reduce the impact on the engine.

What is the estimated cost and time required for repairing issues related to the ECU 128 code?

Since there are many causes of the ECU 128 code, it means the cost of repairs will vary as well depending on the problem. For example, a replacement MAF sensor for Freightliner goes for 281 dollars on Amazon. Depending on your location you could incur additional shipping costs within 100 dollars. Now if you add labor costs, the total cost of repair could be anywhere between 500 dollars and 600 dollars. And that’s just for the MAF sensor. If a damaged component was ignored for a long time, then it can easily damage other engine components making the total cost of repair higher than if the main problem had been fixed on time.

Closing thoughts

In this article I have discussed the ECU 128 code on Freightliner trucks, talking about the causes, troubleshooting, and impact on the performance of the engine. Being that the ECU is one of the most important components of the truck, it goes without saying that the code has to be taken seriously to avoid severely damaging the engine. What’s more important is to remember that at times, the solution might be as simple as a hard reset.

Engineering Coordinator with 5+ years of experience in the automotive manufacturing industry. Currently supporting vehicle development and new model launch activities at Honda Development and Manufacturing of America. Skilled at managing engineering teams, overseeing prototype builds, coordinating testing, and driving continuous process improvements. LinkedIn