The 4L60E automatic overdrive transmission has proven to be a workhorse for GM’s rear-wheel drive cars and trucks. Overdrive gears give vehicles better fuel economy when cruising at highway speeds. However, like any complex mechanical system, the 4L60E is prone to issues over its service life that can disrupt proper operation of overdrive.

- Main Causes Why Your 4L60E Won't Shift Into Overdrive

- Car Symptoms When 4L60E Won't Shift Into Overdrive

- Mechanical Causes of Overdrive Failure

- Solenoid and Electrical Overdrive Issues

- Low Fluid Impacts Overdrive Operation

- How to Diagnose 4L60E Automatic Overdrive Transmission Issues

- Repairs & Fixes

- Preventing Future Overdrive Failure

- Closing Thoughts

Main Causes Why Your 4L60E Won’t Shift Into Overdrive

The GM 4L60E automatic transmission is prone to issues shifting into overdrive (4th gear). Common causes include:

- Worn overdrive band – Friction material wears out, causing slippage and failure to engage OD. Replace band.

- Damaged overdrive servo – Leaks reduce apply force needed for OD. Replace servo and seals.

- Blocked hydraulic circuits – Debris obstructs fluid flow, affecting operation. Flush and replace damaged parts.

- Solenoid problems – Electrical faults disrupt hydraulic control. Test wiring and solenoids.

- Speed sensor issues – Vehicle Speed Sensor helps trigger OD shift. Check sensor and connections.

- Computer programming – Some systems limit OD engagement in certain conditions. Scan for codes.

Let’s see in more detail why your transmission won’t shift into overdrive and how you can identify the culprit and fix it.

Car Symptoms When 4L60E Won’t Shift Into Overdrive

When the 4L60E overdrive stops working, the usual symptoms include:

- High engine RPM at highway speeds – Without being able to engage the overdrive 4th gear at speeds over 45 mph, the engine will run at higher revolutions in 3rd gear. This leads to unpleasant engine drone noise and reduced fuel economy.

- Transmission slipping between 3rd and 4th gears – Harsh shifts may be felt as the transmission struggles to engage overdrive. A slight delay between 3rd and 4th gears is common.

- Check Engine Light illumination – Solenoid or sensor issues can trigger error codes and the Check Engine warning light. Scanning for codes is key for electrical faults.

- Gear hunting between 3rd and 4th – As overdrive function degrades, the transmission may constantly shift back and forth trying to engage 4th gear.

Mechanical Causes of Overdrive Failure

The GM 4L60E automatic transmission relies on precise hydraulic control and robust mechanical parts to smoothly engage each gear range. When issues arise shifting into overdrive, inspecting the internal hard parts and hydraulic system is key to diagnosing the root cause. In my experience overhauling 4L60E transmissions, three common mechanical defects are behind most overdrive failures.

Worn Overdrive Band

The overdrive band provides the all-important friction required to engage 4th gear. This steel-lined band clamps around the overdrive drum when hydraulic pressure activates the overdrive servo. Over tens of thousands of miles, the friction material on the band gradually wears down. Excessive band wear results in slipping and failure to develop enough grip to activate overdrive. Replacing the overdrive band assembly restores the proper clamping force and reliable shifting into 4th gear.

Damaged Overdrive Servo

The hydraulic servo converts fluid pressure into a mechanical force that tightens the overdrive band. The actuator piston must generate around 300 psi to effectively engage overdrive. A cracked or leaking servo will lose pressure-building capability. Without enough clamping force on the drum, the transmission cannot develop 4th gear. Any detected servo damage or leakage warrants replacement with a quality overhaul servo.

Blocked Hydraulic Circuits

Small debris or varnish deposits inside the valve body can obstruct fluid passages critical for overdrive engagement. Contaminants prevent proper hydraulic actuator function, disrupting the timing and pressures needed for smooth shifts. In some cases, a high-quality transmission fluid flush clears out the blockages. But extensive clogs require removal and overhaul of the valve body assembly or complete replacement.

Solenoid and Electrical Overdrive Issues

While mechanical wear accounts for some overdrive problems, electrical faults are behind many 4L60E transmission complaints. Shift solenoids, sensors, and wiring harnesses are susceptible to failure over time, often disabling smooth engagement into 4th gear. Knowing the key electrical components and accurate diagnosis separates simple solenoid swaps from extensive transmission overhauls.

Shift Solenoid Failure

Two electric shift solenoids direct hydraulic pressure to activate the overdrive band and drum. Solenoid A oversees the shift timing from 1st to 4th gears. Solenoid B controls shift firmness and torque converter lockup. Failure of either overdrive solenoid shuts off hydraulic pressure, preventing engagement into 4th gear.

Since the solenoids are easily accessed on the exterior of the transmission, a failed solenoid is one of the simplest repairs. However, proper electrical testing should be performed to confirm a faulty solenoid before replacement.

Bad Torque Converter Clutch Solenoid

The TCC solenoid manages the hydraulic pressure to engage and disengage the torque converter clutch. This solenoid doesn’t activate overdrive directly but a malfunctioning TCC solenoid can disrupt smooth shifting through all gear ranges. Testing the solenoid electrical resistance and observing scanner data helps isolate this potential issue. Replacing the TCC solenoid is the fix once it’s confirmed as the root cause.

Transmission Speed Sensor Failure

Input and output speed sensors track critical data like transmission rpm, road speed, and shift timing. The transmission control module uses this data to properly command shift solenoids and maintain overdrive. A defective input or output speed sensor can completely disable overdrive operation as well as cause harsh shifting. The repair involves replacing the faulty speed sensor and inspecting wiring integrity after verifying the sensor failure with diagnostics.

Low Fluid Impacts Overdrive Operation

While worn hard parts and electrical issues account for many overdrive problems, low fluid level can also prevent smooth engagement into 4th gear. Maintaining proper ATF level is crucial for the 4L60E’s hydraulic system to develop smooth gear shifts. Even with no visible leaks, overdrive operation suffers if the fluid level falls out of specification.

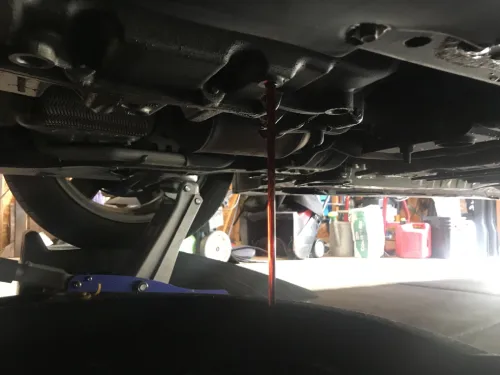

Identifying Fluid Leaks

The most common cause of declining fluid level is external leakage from aged seals and gaskets. The input shaft seal, output shaft seal, pan gasket, and rear seal are all prone to seepage after tens of thousand miles of service. Small leaks may go unnoticed for awhile, slowly draining ATF from the transmission. Identifying the source of external leaks and resealing is critical to restore and maintain the correct dipstick reading.

Checking Fluid Level

Even without external leaks, the fluid reservoir may become underfilled or overfilled over time. The dipstick level should be inspected when the transmission is hot and running. The reading on the dipstick should fall within the designated range – not above the full mark or below the add mark. This precise level ensures the hydraulic pump can deliver sufficient pressure for smooth shifts. Overfilling can cause fluid foaming while underfilling allows shifts to slip and fail.

Fluid Maintenance

Regular ATF changes and filter replacements help maintain overdrive reliability. Old fluid loses its lubricating properties and can introduce harmful deposits. New ATF refreshes the condition, keeping internal components protected. The 30k mile fluid/filter service interval provides affordable transmission longevity insurance.

Making the effort to properly inspect for leaks, check the fluid level, and perform maintenance goes a long way to avoid overdrive issues related to low fluid.

Related content: Does The AC Compressor Affect the Transmission?

How to Diagnose 4L60E Automatic Overdrive Transmission Issues

When a 4L60E automatic overdrive transmission starts displaying symptoms like slipping shifts or failure to engage overdrive, precise diagnosis is key before any repair or overhaul procedures. With over 20 years under the hood, I rely on a meticulous process to correctly identify the root cause of overdrive issues. Proper diagnosis saves time, money and gets vehicles back on the road faster.

Reading Trouble Codes

One of my first steps is to connect a professional scan tool and pull any diagnostic trouble codes stored in the transmission computer. Codes point to specific sensor or solenoid faults detected by the computer. For example, codes P0753 and P0758 indicate issues with the overdrive solenoids. Code P0740 signals a problem with the torque converter clutch solenoid. While not definitive, codes provide an excellent starting point for diagnosis.

Monitoring Gear Speeds

With the vehicle raised on a lift, I’ll monitor rpm speeds in each gear range during test drives. High rpm in 3rd gear with low mph indicates a lack of 4th gear overdrive activation. Excessive slippage between shifts points to clutch or band failure. Gear speeds outside expected values means internal transmission components are not engaging properly. I compare data to specifications to identify faulty ranges.

Testing Electrical Components

Electrical faults account for many 4L60E problems. Using a digital multimeter, I check solenoid resistances, harness continuity, sensor outputs, and voltage signals. Resistance values outside specifications indicate burnt solenoids. Broken wires or loose connections will show up in harness tests. Bad speed sensors won’t generate proper rpm signals. I also wiggle connections and leads to check for any short circuits.

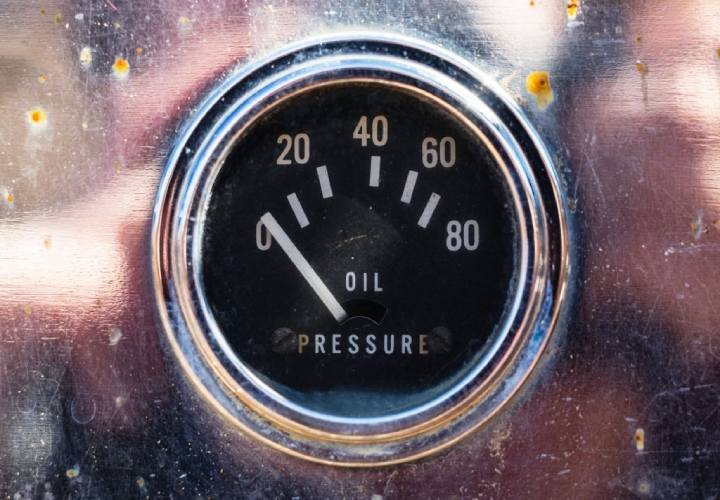

Fluid Inspection

Transmission fluid level and condition provides more vital diagnostic evidence. Low fluid hints at potential external leaks while a burnt smell can mean internal slipping is occurring. Out of range pressures on a gauge would indicate worn pump, clutch or band failure. I drain a sample into a tray checking for metal debris pointing to internal damage. Keeping ATF in top condition promotes longevity.

Linking specific symptoms to test results guides my diagnostic experience to pinpoint the true reason the 4L60E overdrive is malfunctioning. Electrical issues, mechanical wear, hydraulic failures, and computer faults all leave behind unique data fingerprints if you know how to read them. While time consuming, following these strict diagnosis procedures before any repair work begins ultimately saves customers money and frustration in the long run by fixing only the actual problem.

Related content: Can I Drive With a Bad Transmission? Find Out If And When

Repairs & Fixes

When overdrive operation suffers in the venerable 4L60E transmission, there are a range of solutions available to professional technicians to get it smoothly shifting again. Based on thorough diagnostic steps, the most cost-effective yet durable repair can be selected to provide customers with reliable transportation once more.

Fluid Change and Level Correction

One of the simplest first steps is to thoroughly drain the old ATF fluid and replace the filter. Over time, fluid can become contaminated and lose its ability to properly lubricate and transfer hydraulic pressures. Fresh, clean fluid refreshes the system. The fluid level should also be checked and corrected to the proper dipstick reading. Low fluid can prevent engagement into overdrive.

Band and Servo Replacement

Worn friction bands and damaged servos are common in high-mileage 4L60E units. The overdrive band provides the clutching force to engage 4th gear. A worn band with damaged friction material will simply slip and fail to activate overdrive. The servo converts hydraulic pressure to mechanical force to tighten the band. Cracked or leaking servos lack the capacity to develop sufficient band pressure. Replacing worn bands and servos restores positive overdrive activation.

Solenoid Repair

Electrical faults from damaged solenoids or wiring/connector issues are behind many overdrive problems. The shift solenoids control hydraulic flow to the bands and clutches. Speed sensors provide input to the transmission computer. Simple repair procedures like solenoid resistance testing and harness repairs can fix many electrical overdrive issues and save substantial repair costs.

Leak Repair and Fluid Refill

External leaks from aged seals and gaskets will gradually drain fluid out of the 4L60E hydraulic system. Identifying where ATF is seeping from and properly resealing the leak is critical. The system can then be topped off to the proper level to enable smooth shifting. Hard parts causing internal fluid leakage must be replaced during overhaul.

Transmission Computer Recalibration

Sometimes electronic issues stem not from faulty hardware but calibration errors in the on-board computer. Resetting adaptive memory and reprogramming shift points, solenoid timing, and pressure parameters can optimize transmission performance if diagnostics point to computer-related faults.

Transmission Rebuild or Replacement

In severe overdrive failure cases with extensive internal wear or damage, a complete transmission rebuild or replacement may be required. While more costly, this provides assurance that all components meet OEM specifications for many more years of smooth operation. Some repairs can exceed the cost of replacing the 4L60E with a fully remanufactured or junkyard unit.

Getting to the root cause through methodical troubleshooting guides the optimal repair path for 4L60E units. Whether a simple solenoid, complex overhaul, or complete replacement, the proper fix gets customers’ vehicles shifting smoothly once again.

Related content: Do Transmission Stop Leak Products Actually Work?

Preventing Future Overdrive Failure

The 4L60E automatic overdrive transmission is known for its rugged dependability. But like any complex mechanical system subjected to years of demanding use, preventive maintenance is key to avoiding overdrive issues down the road. Based on my experience as a transmission specialist, adhering to a diligent service regimen greatly reduces the risk of overdrive failure in the future.

Drain and Fill Fluid Regularly

Transmission fluid is the lifeblood of the hydraulic system, providing lubrication, pressure activation, andcomponent cooling. Over time, ATF breaks down and becomes contaminated. I recommend a complete pan drop fluid and filter change every 30,000 miles. New ATF refreshes the condition to prevent internal wear and overdrive problems. Check the dipstick level monthly and top off if needed.

Address Leaks Promptly

Common leak points like the input shaft seal, output shaft seal, rear seal, and pan gasket tend to weep after 100k miles. Even small seepage over time will drain ATF levels out of proper range. Identify the source of any visible leakage right away and reseal it. Keep the system airtight to avoid low fluid complications.

Annual Transmission Service

I advise customers to have their 4L60E serviced annually as part of a preventive maintenance routine. A typical service includes:

- Complete ATF exchange to refresh old fluid

- Swap transmission filter

- Inspect for any leaks

- Check and clean electrical connectors

- Test solenoid resistance values

- Road test to check for issues

This small annual investment provides cheap insurance against major repairs down the road.

Use Quality Parts

If the transmission does need internal repairs, I insist on using remanufactured OEM-grade parts. Quality valve bodies, solenoids, bands, clutch packs, and bearings are critical to restore like-new performance and durability. Cheap aftermarket parts often fail prematurely leading to repeated failures. Pay a little more upfront for lasting quality.

Drive Conservatively

Driving style impacts transmission longevity more than most realize. Jackrabbit starts, highway passing at full throttle, and redline acceleration all generate tremendous heat and strain. Gentle takeoffs, coasting to stops, and cruising near the speed limit produces far less internal wear over the long run, keeping your overdrive shifting smoothly for years.

Making transmission maintenance a priority, addressing problems promptly, installing quality parts when needed, and driving with care pays dividends in reliable 4L60E performance. Follow these guidelines and your overdrive can hum along smoothly for 200k miles and beyond.

Closing Thoughts

When overdrive function suffers in the rugged 4L60E transmission, getting to the root cause through complete diagnostics is critical before any repair or overhaul procedures. Mechanical wear, hydraulic problems, electrical faults, fluid leaks, and computer issues can all contribute to 4L60E overdrive failure. Identifying the true underlying problem dictates the most cost-effective repair path to restore smooth and reliable operation.

Addressing overdrive issues promptly also prevents detrimental secondary damage from occurring inside the transmission. Allowing excessive slippage and component wear to continue unfixed raises repair costs substantially. Beyond repairs, adhering to diligent preventive maintenance greatly reduces the risk of overdrive failure down the road. Simple steps like regular fluid changes, leak repairs, annual servicing, and driving gently keep transmissions in top shape.

With meticulous troubleshooting and quality repairs when needed, the venerable 4L60E automatic overdrive unit can deliver hundreds of thousands of miles of dependable service. Proper maintenance and care ensures your transmission shifts smoothly for the long haul.

Engineering Coordinator with 5+ years of experience in the automotive manufacturing industry. Currently supporting vehicle development and new model launch activities at Honda Development and Manufacturing of America. Skilled at managing engineering teams, overseeing prototype builds, coordinating testing, and driving continuous process improvements. LinkedIn