The P11DB diagnostic trouble code is set when there is a problem with the nitrogen oxide (NOx) sensor. It indicates an issue with the NOx sensor current performance bank 1 sensor 1 in Chevrolet or GMC diesel vehicles.

The possible causes of the P11DB code include a faulty NOx sensor, an open or shorted wiring harness running to the sensor, or a general electrical connection problem. These problems will make it challenging for the Powertrain Control Module (PCM) to determine the amount of nitrogen oxide in the exhaust gasses.

- What Does It Mean? (P11DB NOx Sensor Current Performance Bank 1 Sensor 1)

- What Are the Causes of the P11DB Code?

- How Can You Fix the P11DB Code?

- How Much Does It Cost to Fix P11DB Code?

- What Is a NOx Sensor On a Duramax Engine?

- What Happens When A NOx Sensor Fails?

- Can I Drive with a Faulty NOx Sensor?

- What Happens If You Don't Replace NOx Sensors?

- In Summary

Read for details about the P11DB code, including its causes, how to fix it, and the estimated repair cost. We will also answer related questions regarding what you should do when this code is active. Let’s dive right in!

What Does It Mean? (P11DB NOx Sensor Current Performance Bank 1 Sensor 1)

In simple terms, the P11DB code indicates a fault with the NOx sensor or its connectors. But what does the sensor do in your car? The development of nitrogen oxide sensors began as early as the 1990s and has become standard equipment for vehicles equipped with diesel engines. They measure the level of oxygen and nitrogen in the air intake system (upstream) and exhaust (downstream). The P11DB code becomes active when there is a significant variation in the level of these gasses.

The level of oxygen and nitrogen in the exhaust can vary if the NOx sensors are faulty. Other underlying factors can also cause significant variations that the sensors will read and report to the PCM.

In other words, faulty sensors report erroneous data to the PCM, and underlying conditions can cause an actual change in nitrogen oxide levels. These two conditions will cause the code P11DB to pop up on you scanner.

What Are the Causes of the P11DB Code?

The code can be set if there is a problem with the upstream or downstream NOx sensors or harnesses. Sensors and the control module all communicate through an electrical network, which is created by electrical wiring. Any problem with it hampers the working of the circuit. Let’s break it down for better understanding.

01. Faulty Upper NOx Sensor (part number 24000395 p/n)

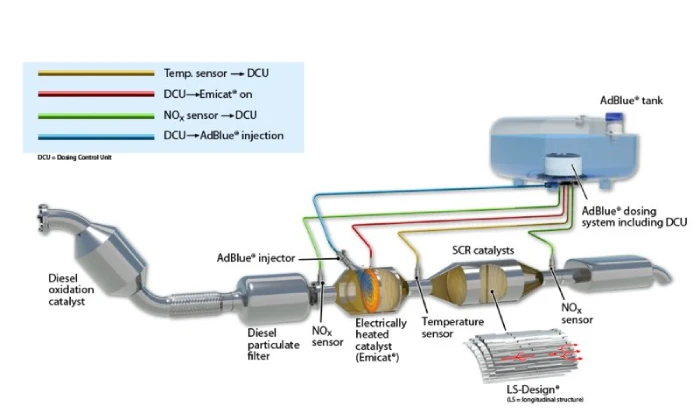

NOx sensors are the ears and eyes of the control module. The selective catalytic control system uses two sensors; one in the upstream and the other in the downstream. The upstream NOx sensor measures the nitrogen and oxygen levels in the intake air, and the downstream one checks the oxygen and nitrogen levels in the exhaust.

The control module compares the two data sets obtained from the upstream and downstream NOx sensors. The difference should be within the specified range for allowable emission of these gasses into the atmosphere. But if either an upstream or downstream sensor is faulty, the function of the selective catalytic reduction system is compromised.

The NOx sensors are a vital component of the system but are also susceptible to damage. Their sensitive part that detects nitrogen oxide level in the exhaust gasses suffers from soot buildup. That can cause the control module to throw up the fault code because of inaccurate data. They can also be damaged by moisture in the exhaust.

02. Harness Damage

This is self-explanatory. The electrical signal travels through wires from the source to the destination, which is how NOx sensors and control modules communicate. The system uses a bundle of wires called a harness to exchange information.

However, damages can occur at the wire harness or wear out over time as they become stiffened due to exposure to external elements. That can cause an open or short circuit, which affects either the power line to the NOx sensors or the data line from the sensors to the control module.

03. Loose Connection

This is the same as the damaged wire harness. Loose connections disrupt the smooth flow of electrical signals through wires, interfering with the entire system’s operation. Electrical cables can become loose at the connection point due to corrosion that eats away the copper. Unnecessary tension in the system can also pull the wires, eventually loosening them.

Related content: Can a Bad O2 Sensor Cause Misfire? Causes & Fixes

How Can You Fix the P11DB Code?

Fixing the code P11DB in Chevrolet or GMC cars involves diagnosing the cause and solving the identified issue. As mentioned, the possible causes of the P11DB code include faulty NOx sensors, loose connections, and damaged wire harnesses. So, start your diagnosis by checking these components.

Check the NOx sensor and replace the damaged ones. A faulty sensor leads to increased DEF consumption and low mileage per gallon. It tells the Engine Control Unit (ECU) the amount of DEF to be injected into the exhaust before it enters the SCR. So. Replacing faulty NOx sensors will solve the problem.

But if that does not correct the fault, check the harness for any damage or loose connections. They will likely be the culprit if your sensors are working correctly.

After fixing the faulty component, the fault code that turns on the check engine light will reset itself when the system initializes.

How Much Does It Cost to Fix P11DB Code?

The cost of fixing the P11DB code depends on many factors, including your location and the parts to be replaced. Diagnosing this problem often takes one hour of labor. You can save if you are a DIYer and want to do it yourself. But if you need expert mechanics to help you, expect to spend about $70-$150 on diagnosis alone.

Once the diagnosis is complete, you will be charged further for fixing the defective part. If the NOx sensors are the problem, a new OEM part usually ranges from $450 to $7500. These are just estimations; it can cost higher in some areas. Fortunately, you can find the best deals on an aftermarket part from a reputable manufacturer, but it should meet the OEM specifications.

But you can escape the high replacement cost by cleaning the soot covering the NOx sensor. However, that won’t be possible if they are damaged by moisture. You will have no other option but to replace it.

What Is a NOx Sensor On a Duramax Engine?

A NOx sensor is a component of an after-treatment system in the vehicle that measures the level of nitrogen oxide in the exhaust. It was developed as part of the diesel engine system to make the vehicle eco-friendlier. The after-treatment system reduces the harmful gasses in the exhaust, protecting the environmental damage by diesel vehicles. It uses a Urea-based SCR system to achieve this purpose.

NOx sensors are usually available as a set of two; upstream and downstream sensors. They are an integral part of the after-treatment system consisting of DPF and an SCR catalyst.

What Happens When A NOx Sensor Fails?

As with many electronic components in your car, the NOx sensors will eventually fail. But what happens in that case? We need to understand its role before we get into the symptoms associated with a faulty NOx sensor.

As mentioned, the ECU uses the data from the NOx sensor to determine the amount of DEF it should inject into the exhaust before it enters the SCR catalyst. The data from the NOx sensors are within a specific bandwidth. But the erratic information it gives will flag an error in the ECU. Your vehicle will go into limp mode, also known as emergency mode. This will prevent any further damage to other important components such as engine or transmission.

When the NOx sensor fails, the Check Engine Light illuminates the dashboard. That is because of the active P11DB code. You will also experience increased fuel consumption because ECU again needs data from NOx sensors to determine the amount of fuel to inject into the engine. The engine can either run rich or lean. There are also cases of jerkiness, misfiring, and unstable idling.

Can I Drive with a Faulty NOx Sensor?

Yes, you can still drive with a faulty NOx sensor, but it is not recommended. You can only drive your car with a malfunctioning sensor for a short time, with the engine likely to run rich and overuse DEF. However, the ECU will eventually switch the vehicle to a limp mode to protect the engine from any possible damage.

It would be best if you fix a faulty NOx sensor as soon as the problem occurs. It will help you comply with the stringent emission laws and keep your car in good condition. Replace or repair it at the next opportunity.

Related content: Does idling hurt your diesel engine?

What Happens If You Don’t Replace NOx Sensors?

Replacing a faulty NOx sensor should be a priority. It is a vital component that allows your engine to run efficiently and reduce emissions of harmful gasses to the environment. If you don’t replace or clean a dirty NOx sensor, you risk violating the emission laws.

NOx sensors provide valuable data to ECU to control various processes, such as the fuel supply to the engine and DEF to inject into the exhaust. Failing to replace a faulty sensor means these processes will run erratically. You will experience increased fuel consumption, overuse of DEF, jerking, rough idling, and even limp mode. The ECU activates that emergency mode to avoid further damage to the engine.

Auto experts advise replacing the faulty NOx sensor as soon as you realize it to prevent associated damages and problems.

In Summary

While not a frequent DTC, the P11DB code happens occasionally in Duramax engine-powered vehicles, such as Chevy and GMC. It is most likely caused by a failing upper NOx sensor. As discussed already, each diesel engine needs two NOx sensors to monitor the oxygen and nitrogen levels in the air intake system (upstream) and exhaust (downstream).

You can still drive the car after you get a P11DB error code, but you will experience poor MPG, increased DEF consumption, and car shaking. Eventually, the car will go into limp mode to prevent any further damage.

Brian is an auto technician who writes DIY repair articles and creates how-to videos for MechanicAsk. He focuses on common repairs like brakes, oil changes, and lighting. Brian draws on his 5 years of dealership experience to explain repairs in an easy-to-follow manner, even for novice do-it-yourselfers. His technical articles always include detailed tool lists, supply checklists, and visual guides.